CERAMIC PRINTING

Ceramic 3D Printing as a Fabrication Technique

Exploring ceramic 3D printing was an excellent opportunity to expand my material knowledge and skill set as an industrial designer. It’s always beneficial to have experience with a range of materials, and ceramic is particularly versatile and interesting. This project allowed me to create complex and intricate shapes that are difficult to achieve using traditional ceramic techniques. The precision and consistency offered by ceramic 3D printing are particularly valuable in industrial design, allowing for greater trial and error.

Project Type

Individual Project | Prototyping

Program

Topics in INDD | New Craft | ECUAD

Output

Prototype

Material

Clay

Year

2023

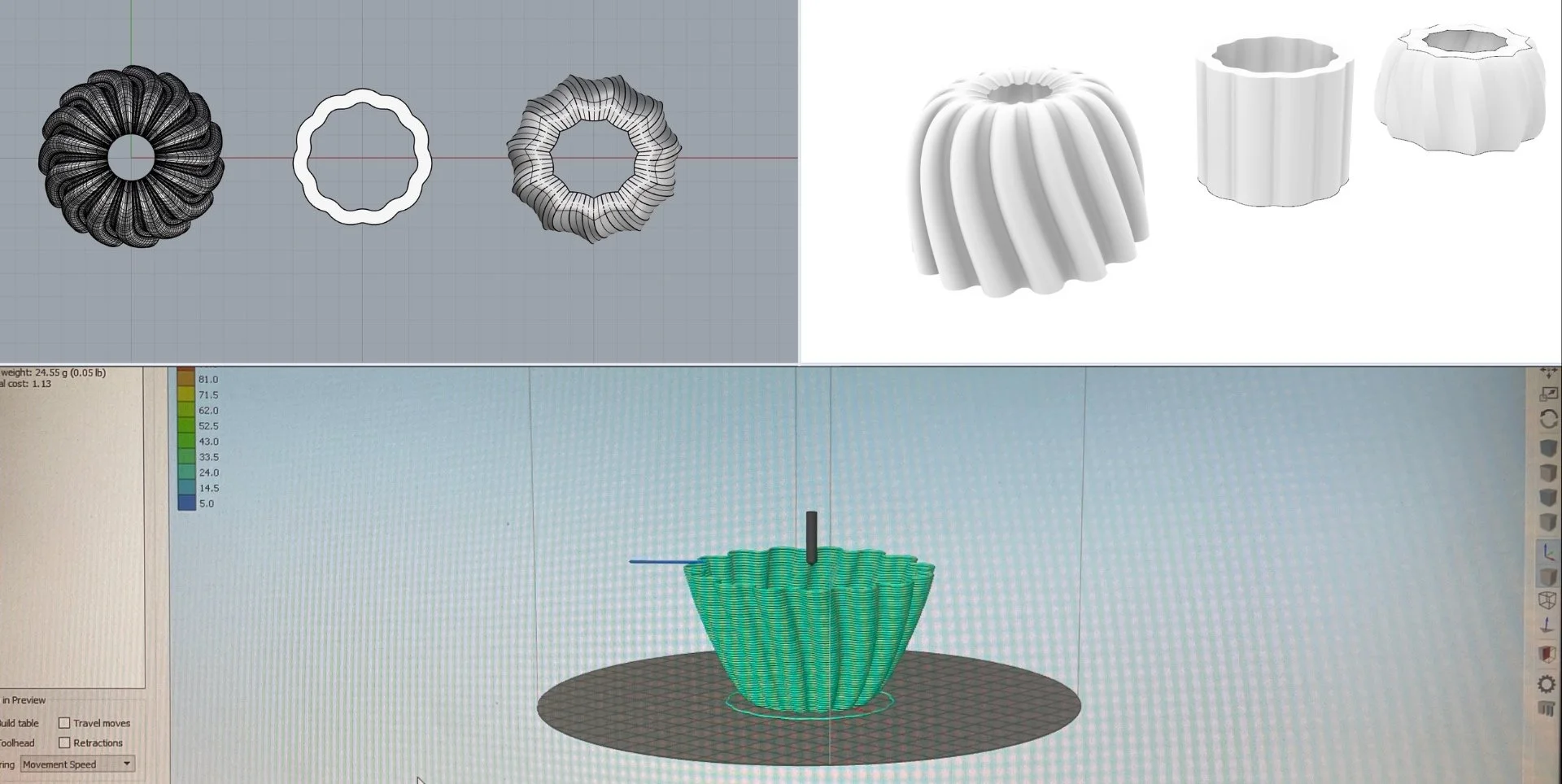

Initial Explorations and Limitations

Ceramic 3D printing, despite being a digital additive manufacturing process, has its limitations. Unlike other 3D printers that use support material, it was crucial to design shapes that are simple and self-supporting within limited angles. My journey began with lofting simple silhouettes, a foundational step that helped me understand not only the printer but also the setup process in the slicing software (Cura). This initial phase allowed me to learn about the minor tweaks necessary for immediate model adjustments.

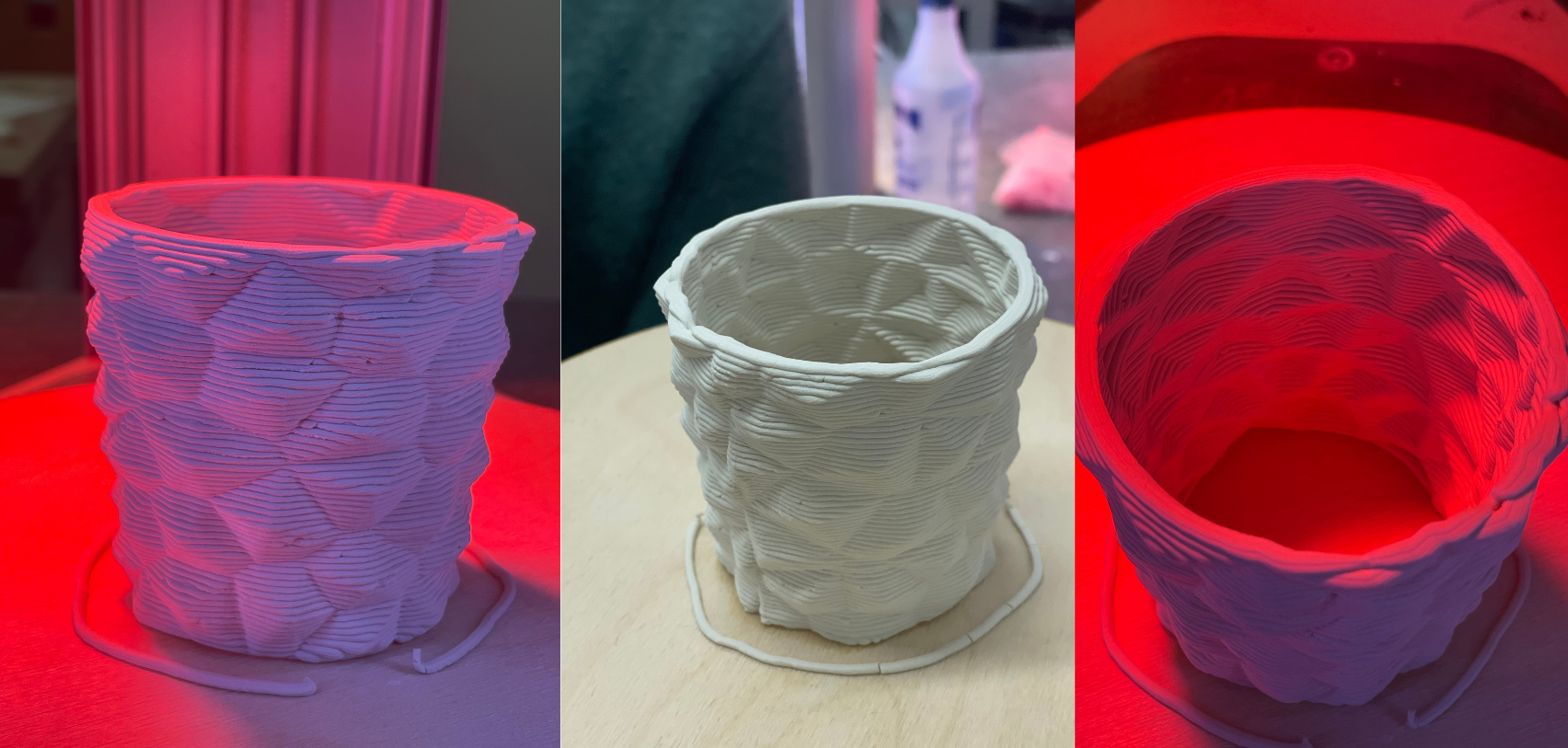

Faceted Forms

After successful experiments with lofting and twisting, I ventured into parametric shapes using Grasshopper. I modeled simple faceted forms to test their printability, keeping the scale and count low for initial prints. This phase was crucial in pushing the boundaries of what could be achieved with ceramic 3D printing.

Lofting and Twisting

Starting with simple lofted shapes, I gradually explored more complex geometries by twisting these forms. This progression from basic to intricate designs provided a deeper understanding of the printer's capabilities and limitations.

Final Reflections

Overall, ceramic printing has been a valuable craft to learn and practice. Previously, clay only interested me as a rapid prototyping material, but this project marked the first time I used it for a final fabricated outcome. The experience has been satisfying, revealing the material's peculiarities and expanding my thinking on its potential applications. Whether for prototyping or creating finished pieces, the speed and precision of the machine have transformed my perception of how I can use clay in the future.

This project underscores the transformative potential of ceramic 3D printing, merging traditional craftsmanship with modern technology to unlock new creative possibilities.